views

Power Looms: The Transformation of Textile Manufacturing, 1844–2004

The history of textile manufacturing is deeply intertwined with technological innovation, and few inventions have had as profound an impact as the power loom. From its creation in 1844 to its evolution throughout the 20th century, the power loom revolutionized the textile industry, transforming it from a labor-intensive, artisanal craft into a mechanized, mass-production powerhouse. The history of power looms is not only a tale of industrial progress but also one of labor struggles, social upheaval, and global economic transformation.

In this article, we will explore the power loom’s development, its role in the Industrial Revolution, the technological advancements that improved its efficiency, and its impact on both the textile industry and the lives of workers over the course of 160 years. Through the lens of suspense, excitement, and deep analysis, we will uncover how the power loom reshaped the world of textile manufacturing, its effects on the global economy, and its legacy in the modern industrial landscape.

The Birth of the Power Loom: 1844

The story of the power loom begins in the early 19th century, during the Industrial Revolution, a period of rapid technological advancement that radically transformed society. Textile manufacturing, which had once relied on hand-spinning and hand-weaving, became one of the first industries to embrace mechanization. The spinning jenny and water frame, developed earlier in the century by James Hargreaves and Richard Arkwright, had already mechanized the spinning process, but the loom, which wove the yarn into cloth, remained a manual operation.

The power loom was the key to finally mechanizing weaving, and it was Edmund Cartwright, an English clergyman and inventor, who is credited with its invention in 1784. However, the early designs of the power loom were flawed and inefficient. It was not until 1844, when George C. H. Brayton and William Radcliffe introduced a new, more refined version of the power loom, that it gained widespread acceptance in the industry. This new model, driven by steam engines and later electric motors, allowed manufacturers to weave fabric much more quickly and efficiently than ever before.

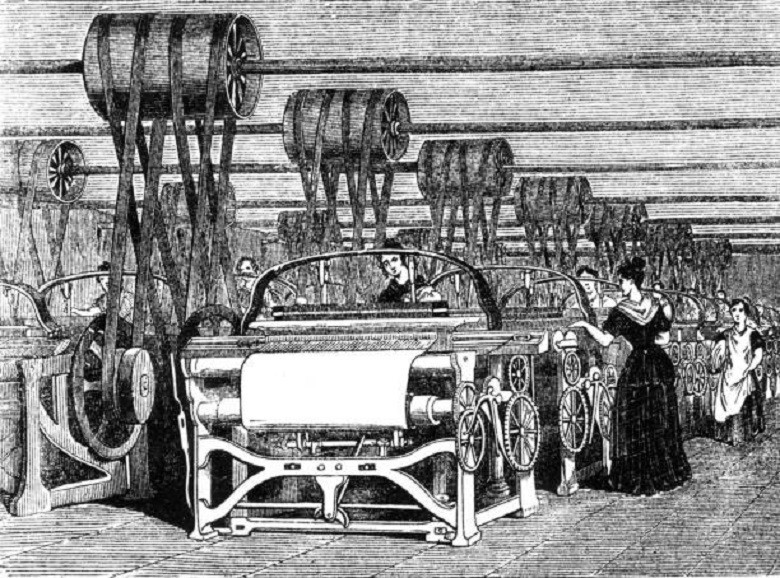

As power looms spread across Britain, they began to replace traditional handlooms in factories, particularly in the burgeoning textile towns of Manchester, Lancashire, and Leeds. The power loom was capable of weaving fabric at an astonishing rate, with one machine often capable of replacing several handloom weavers. As a result, production costs plummeted, and the availability of cloth skyrocketed. The implications for the textile industry were nothing short of revolutionary.

The Impact of Power Looms: Changing the Fabric of Society

The introduction of the power loom marked the beginning of a new era in the textile industry. As the machines became widespread, the textile factories that housed them grew in both size and number. The factory system that emerged during the Industrial Revolution created new economic opportunities, but it also introduced new social challenges.

The mechanization of weaving allowed manufacturers to produce textiles at unprecedented scales, fueling the global demand for cotton and other fibers. As British factories churned out cotton fabrics, textiles became an essential export, cementing Britain's status as the world's leading industrial power. However, as these factories expanded, so too did the demand for cheap labor.

The power loom, like many machines of the era, was initially seen as a threat by workers. Luddite riots, named after the mythical figure Ned Ludd, were a direct response to the rise of mechanization in industries like textiles. In 1811-1812, Luddites in northern England began smashing power looms, fearing that these machines would render their traditional jobs obsolete. Though the movement was eventually crushed, it foreshadowed the tension between labor and technology that would characterize much of the Industrial Revolution.

Despite the resistance, factories continued to grow, and with them, so did the demand for workers. However, the new power loom-driven system had significant consequences for labor. While the machines increased productivity, they also replaced many skilled handweavers, and workers were forced to adapt to a new, factory-based way of life. The power loom accelerated the growth of the working class, with men, women, and children working long hours in dangerous, often oppressive conditions for low wages.

Technological Advancements and the Rise of Automation: 1850s–1900s

By the mid-19th century, the power loom had become a staple of the textile industry, but it was far from perfect. Early models were prone to breakdowns and required frequent maintenance, but engineers soon began improving upon the original designs. The 1880s saw a major shift with the introduction of the automatic loom, which made it possible for the machines to continue weaving without the need for constant human intervention.

The Jacquard loom, invented by Joseph Marie Jacquard in 1804, was also an important precursor to modern automated looms. This early mechanical loom used punched cards to control the pattern of the fabric being woven, a concept that would later influence the development of the computer. By the late 19th century, the automated power loom became an efficient and reliable tool for mass production.

One of the most significant technological advancements in loom manufacturing came with the advent of electricity. In the early 20th century, electric power replaced steam as the primary source of energy for factories, allowing looms to run more efficiently and with greater precision. The ability to power looms electrically marked the beginning of a new era in textile manufacturing, characterized by even greater automation and speed.

As looms became more reliable and faster, textile manufacturers could produce fabrics in larger quantities, leading to the expansion of the global textile market. By the early 20th century, power looms were widespread not only in Britain but also in the United States, Germany, and other industrialized nations.

The Decline of Power Looms: 20th Century and Beyond

While the power loom was once the driving force behind the textile revolution, it began to face competition in the late 20th century. The rise of synthetic fabrics, changes in consumer demand, and the globalization of manufacturing contributed to a decline in traditional textile manufacturing in industrialized countries.

By the mid-1900s, power looms were increasingly replaced by more specialized machines that could weave complex fabrics more quickly and with fewer workers. The automation of textile manufacturing reached new heights with the development of computerized looms, which allowed for even more precision in fabric design and production.

At the same time, globalization shifted textile production to lower-cost countries in Asia, where cheap labor and lower regulatory standards allowed companies to produce textiles at a fraction of the cost. Countries like China, India, and Bangladesh became major players in the textile industry, while traditional textile factories in Europe and the United States began to close or relocate.

Despite this shift, the legacy of the power loom remains evident in the modern textile industry. Today, advanced looms are still used to produce a wide range of fabrics, from the simplest cotton sheets to complex fabrics used in fashion and aerospace materials. The fundamental principles behind the power loom—automation, efficiency, and mass production—are still at the heart of modern textile manufacturing.

The Legacy of Power Looms: Social, Economic, and Cultural Impact

The power loom’s impact on the textile industry and society cannot be overstated. Beyond its technological advancements, the power loom changed the very nature of work. It played a central role in the rise of industrial capitalism and the growth of the global economy. It facilitated the mass production of textiles, making fabric more affordable and accessible to a broader population.

However, the rise of the power loom also had profound social implications. It contributed to the rise of factory-based labor, which was often exploitative, especially in the early days of mechanization. Workers, particularly women and children, toiled in dangerous, unhealthy conditions for long hours, with little regard for their well-being. Labor movements and the trade union movement arose in response to the harsh working conditions in factories, with workers demanding better pay, fewer working hours, and safer conditions.

Today, the power loom’s legacy is one of technological progress and labor struggles, but also one of global interconnectedness. The textile industry is now a massive global industry, worth trillions of dollars, and the power loom remains a symbol of the enduring power of industrialization to reshape the world.

Conclusion: The Power Loom’s Enduring Influence

From its invention in the early 19th century to its widespread use throughout the Industrial Revolution and beyond, the power loom has played a central role in shaping the textile industry, global trade, and social change. Its story is one of technological innovation, social transformation, and economic upheaval. Over the course of 160 years, the power loom’s journey from a simple mechanized machine to a key component of modern manufacturing reflects the broader changes that have shaped the world of industry, labor, and globalization.

As we look to the future, the power loom’s legacy continues to influence the ways we produce and consume goods. In a world of ever-advancing technology, the basic principles of the power loom—automation, speed, and efficiency—remain integral to the continued evolution of global manufacturing. Whether in the form of advanced automated looms or the complex supply chains that drive textile production today, the power loom’s story is far from over.

Comments

0 comment